DPF cleaning to save costs

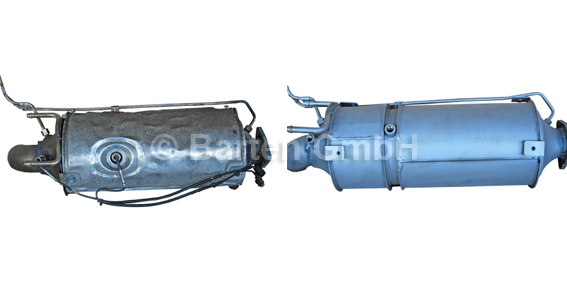

By means of our professional diesel particulate filter cleaning, we offer you a much more cost-effective alternative to replacement. We clean dirty soot filters quickly, reliably and safely!

While a new DPF purchase is often associated with high costs (up to 3000, – Euro), the complete particle filter cleaning can be implemented at Barten GmbH for 375, – Euro!

Thus a particle filter provides for smaller duties with the KFZ tax. Especially in environmental zones, driving a car without a particulate filter is almost impossible, since vehicles without a soot filter have no chance of getting a green sticker.

In the long term, regular and professional cleaning also pays off in terms of the driving costs incurred. This is because the more soot and ash are deposited, the more the exhaust backpressure increases. Higher fuel consumption results from the increasingly frequent self-regeneration of the vehicle. In any case, the filter should be cleaned at regular intervals.

In addition, a cleaned particulate filter contributes to an increase in value when selling the car.

DPF cleaning to protect the engine

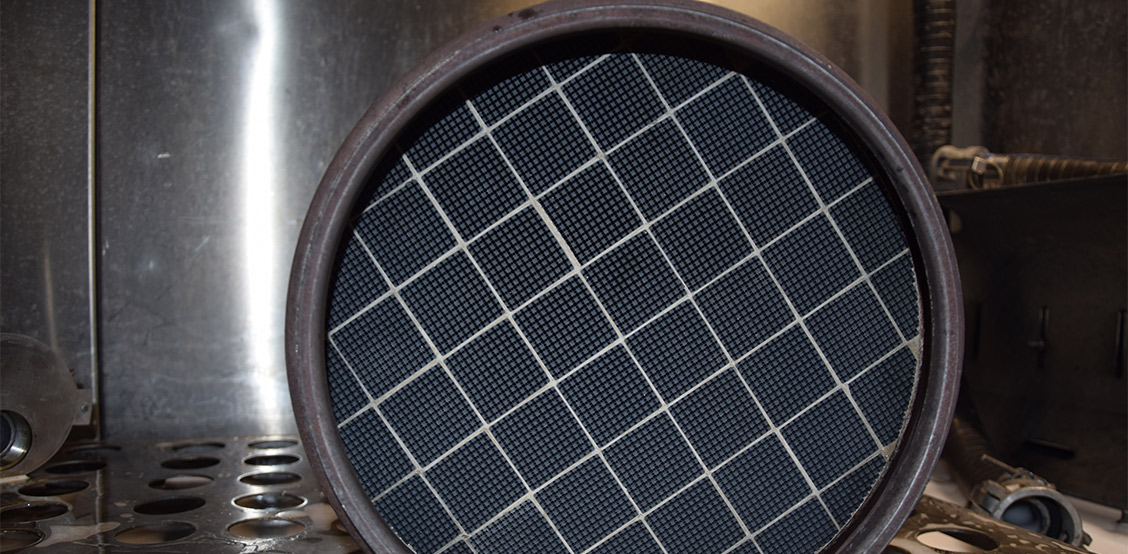

If you do not have your diesel particulate filter cleaned in time, it can become clogged and even irreparably damaged.

The attached parts of the engine can also be damaged by a clogged DPF. Then the costs skyrocket and a trip to the workshop is unavoidable.

Especially if the exhaust gases can no longer flow freely through the DPF, costly damage to the turbocharger/engine quickly occurs.

Due to the permanently increasing exhaust backpressure behind the turbine wheel, the turbocharger shaft is extremely stressed and damage can occur to the axial bearing and compressor wheel.

The turbocharger does not come up to speed due to the clogged DPF (normal is up to 180 thousand revolutions per min., depending on model and type). This results in an unfavorable fuel/air mixture, creating even more soot and ash. In addition, the high backpressure can result in an increased engine oil level (as unburned diesel is forced past the piston rings into the oil sump).

The diluted engine oil can eventually cause capital engine damage (lubricant film breakage).

DPF cleaning to protect the environment and health

One of the reasons for the much-discussed global warming is clearly the increase in CO2 pollution. In order to counteract the developments of global warming, regulations and limit values are increasingly being tightened. Especially for traffic in large cities, the limits have been reduced in order to reduce the health hazards posed by unpurified exhaust gases.

Having the diesel particulate filter professionally cleaned at regular intervals therefore has the effect of protecting our environment in many ways.

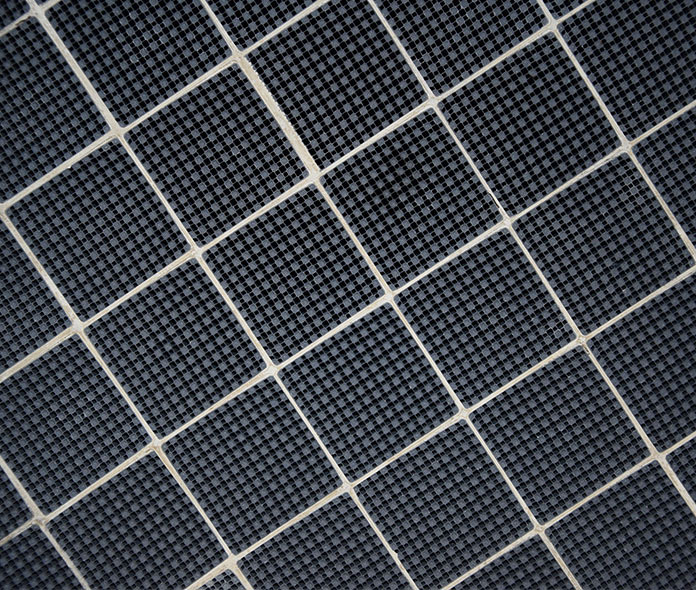

A clean, free, diesel particulate filter reduces exhaust emissions and ensures harmless levels of particulate matter.

In this way, resources are conserved through the reprocessing or reuse of the particulate filter. This means that no new particulate filters have to be manufactured and then coated, saving valuable material and energy.

Furthermore, a cleaned diesel particulate filter helps to reliably comply with particulate limits, which in turn can noticeably reduce CO2 pollution. Soot from diesel engines, for example, is now blamed for five percent of cancers of the upper respiratory tract.

Every particulate filter that is used or cleaned up therefore makes a small contribution to the preservation of our environment and our living space.