Save time & money with DPF cleaning at Barten!

We, Barten GmbH, have been carrying out professional soot particle filter cleaning since 2000, which frees the filter from all residues by 98%. You are definitely at the right place if you want to have your particulate filter cleaned professionally and innovatively.

Due to our innovative procedure you can do without a costly replacement. After cleaning, the filter has the values of a new filter.

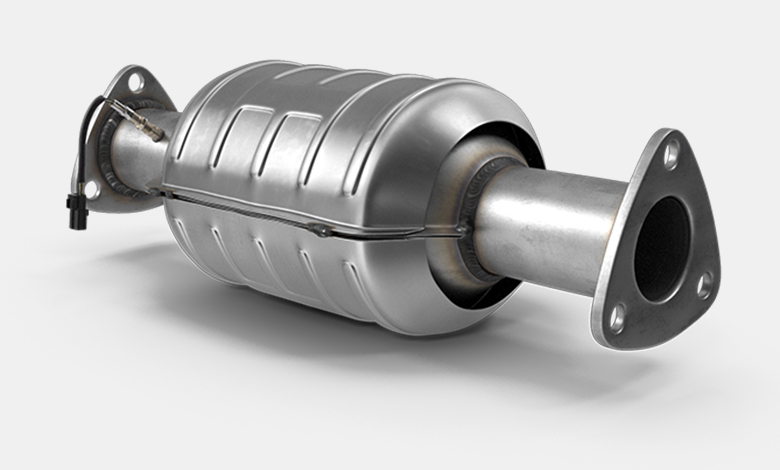

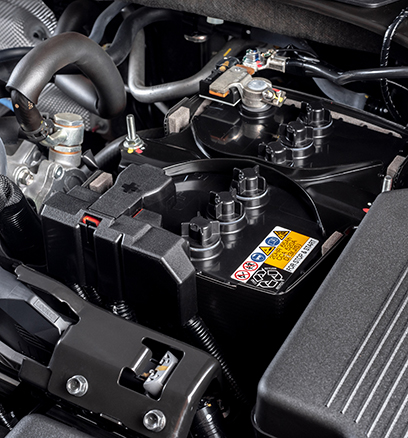

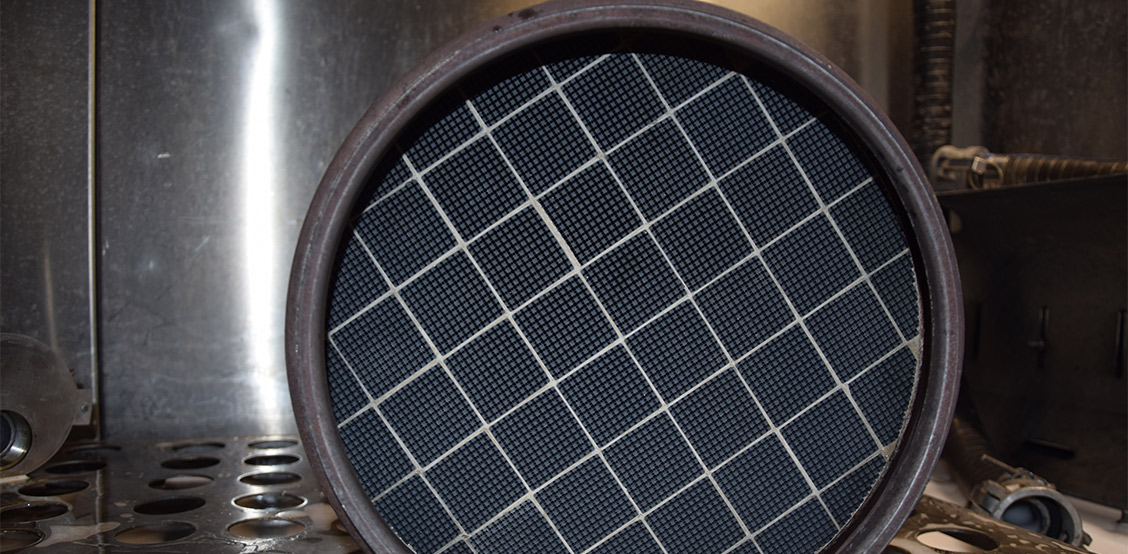

During diesel particulate filter cleaning, we first measure the clogging/loading of the particulate filter with an air flow and weight measurement. After analyzing the severity of the contamination, the soot filters are cleaned in a thermal-mechanical process until they are approximately 98% free of all residues, primarily: the soot and ash residues, and have reached the reference value for the respective filter type. This often requires several particle filter cleaning cycles!

Particle filter cleaning at Barten – by means of thermal mechanical cleaning

In our many years of activity as a specialist company for soot filter cleaning, we have taken a closer look at many cleaning approaches and, in the sense of further development and improvement of our company’s service, we have also tested/experienced various techniques.

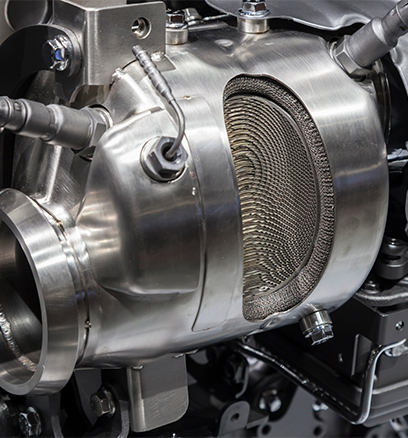

For soot filter cleaning, we still rely on the thermal-mechanical and TÜV-tested cleaning process developed by us. The filter is cleaned in the dismantled state, without cutting open the housing and without additives/chemicals. This procedure comes closest to the self-regeneration of the vehicle developed by the manufacturers, which relies on the burning off of soot by increasing the combustion temperature (internal/external regeneration), whereby we additionally remove the ash! Likewise, burnout preserves the coatings and materials located in the catalytic converter, DPF or particulate catalyst, which are necessary for optimal exhaust gas aftertreatment.

Imagine a classic stove with a glass pane. The black soot that appears at the beginning and settles on the pane burns off when the right temperature is reached. Only ash remains in the fireplace. This can then be easily removed during furnace cleaning.

>>In our process, we perform this in a figurative sense in a similar way. The ash is gently removed by us after the firing process, in a special mechanical process. Deposited ash can be effectively removed only in the dismantled state. >>

However, if the sensitive kiln glass is cleaned with harsh chemicals, abrasives or liquids, this will result in cleaning, but scratches and attacked surfaces / sealing strips may result. Also the disposal of the loosened dirt, with the cleaning agents taken to the help, falls now. Here it is uncertain how some means affect health and the environment during application and disposal. Similar references can be transferred to the different, on the market offered, methods for DPF cleaning.

Avoid costly DPF replacement in the long run with DPF cleaning from Barten.

When a professional diesel particulate filter cleaning is performed, DPFs can be fully reconditioned and have the values of a new filter. So, with proper DPF cleaning, a particulate filter will last the life of the car and will not need to be replaced with an expensive new filter.

Here you can see our thermal-mechanical cleaning process compared to other DPF cleaning processes.

Particle filter express cleaning (within 24 hrs.)

Our customers’ filters are cleaned until they are approximately 98% free of soot and ash residues and have reached the reference value for the respective filter type.

The duration of DPF cleaning therefore depends on the degree of contamination (mileage-related). Generally, we need about 1-3 working days (Monday to Friday) for DPF cleaning, but on average 80% of the filters are cleaned within 24 hours.

Fast and easy processing for DPF cleaning

If you need to have your DPF cleaned, you can rely on us for fast and uncomplicated processing.

You can deliver the removed DPF to us, have it picked up by our UPS pick-up service at an address of your choice, or send the filter to us yourself. (The advantage of UPS pickup is a reduced shipping time of 1 day).

If you send us the filter, please print out the online order form (you will receive this by email after placing your order). Include this with the package to ensure proper allocation of the filters. Please pack the soot filter neatly in a cardboard box and pad it sufficiently. If you have selected package pickup, please also print out the additional shipping label and affix this to the package. The UPS driver will pick up the package at the time you select.

Your guarantees with DPF Cleaning by Barten

Satisfaction Guarantee: We give a 6-month guarantee on our cleaning service … no IFs or BUTs! If your filter is reloaded within this time (e.g. due to a defect in accruals or defective components in the engine), we will clean it again – free of charge – for you.

Cleanliness guarantee: The soot filters cleaned by us are cleaned as long and as often as necessary until they are 98% free of soot and ash residues and reach the measured values of a new filter.

Money-back guarantee: If the filter does not reach the reference value required by us even after several cleaning attempts, then you do not have to pay anything for the cleaning. The filter will then be returned to you as “uncleaned” and no longer usable -free of charge.

A 2nd cleaning after the 6-month warranty period is carried out from 7-12 months at a special price of 150 €.

If you have the filter removed/cleaned by a partner workshop, the free warranty period is extended from 6 to 12 months.

Facts and figures about the package removal

If you need to have your particulate filter cleaned, you can conveniently send it to us by mail.

To calculate the belt dimension, you can use our online belt dimension calculator.

You can find it on our order form page.

The belt dimension is made up as follows:

girth (full length around the package or 2x height + 2x width) + longest side.

Girth up to 330cm and longest side under 150cm = NO additional costs

For larger packages, the following additional costs will apply:

Girth up to 330cm and longest side over 150cm = additional costs 25,- Euro net

Girth from 330cm up to max. 419cm and longest side max. up to 180cm = additional costs 95,- Euro net

Insufficiently packed parcels e.g. only foil/paper and sticking out = additional costs 25,- Euro net

Packages must not weigh more than 32kg

No costs in case of failed DPF cleaning

If you send us your DPF for cleaning, but it should be defective, there are no costs for you for the assessment and testing of the DPF. You only have to pay the shipping costs. If the DPF can no longer be cleaned, the costly replacement is unfortunately usually unavoidable.

Easy payment for diesel particulate filter cleaning

After the incoming inspection, you will receive an e-mail about the receipt and condition of your diesel particulate filter. In addition, our invoice is attached to this e-mail. You are welcome to send us a payment receipt of the bank transfer as proof or you have the option to pay directly via PAYPAL. For private customers, we will ship the cleaned filters only after we have received the payment/proof of the bank transfer. Payment by cash on delivery is also possible.

For workshops, the DPF cleaning is done on account.

You must observe the following when installing the filter!

Please follow our installation instructions. You will receive these with the return of your cleaned DPF.

In it you will find all the important information about the reset and a checklist with possible sources of error.

Benefit as a partner workshop for DPF cleaning

As a car workshop, you receive DPF cleaning at our favorable workshop rate.

You can make a price inquiry via our contact form. Here you have the possibility to upload your trade license / letterhead for registration and verification.

Select as subject: Conditions for workshops.

How to register!

You have a workshop and would like to become a partner workshop of Barten? Send an inquiry via our contact form and select as subject: Become PW.

We will then send you all the information/benefits of a partnership by email.

What distinguishes us as a good specialist company for DPF cleaning NRW

In the meantime there are a lot of cleaning offers for DPF cleaning NRW on the internet. For the customer it is difficult and time-consuming to get an overview from the multitude of offers and to distinguish the serious from the dubious providers, if he has to have his DPF cleaned. We have provided you below with a checklist of important quality characteristics that, in our opinion, make up a good professional company for DPF cleaning:

Checklist for choosing professional providers for soot filter cleaning:

Is the filter cleaned while closed or is it opened? (The opening of the filter can lead to an expiration of the operating license, since at the original part a type change takes place).

Is the ceramic of the filter replaced by e.g. inexpensive/non-original ceramic cores? (this is also a design change to the original part, which can lead to invalidation of the operating permit if this has not been approved by the German Federal Motor Vehicle Authority)

Is the filter cleaned when removed? (DPFs such as wall-flow, ceramic, bypass, deep-bed or sintered metal filters can only be cleaned in their dismantled state at new-value quality).

Is the process / cleaning procedure TÜV tested or only the machinery? Are the TÜV certificates visible/public and up to date? (e.g. some companies advertise with the TÜV, but only the machines are TÜV tested).

In terms of waste disposal, it should be certified and comprehensible that the waste materials are disposed of professionally and in a qualified manner (e.g. ISO certification for environmental management).

Is there a certification for quality assurance? (e.g. according to ISO)

Which process is used? (See: What are the cleaning methods?)

Is there a warranty for the customer?

Are there installation instructions for the customer (instructions for installation, resetting and possible sources of error that lead to a renewed premature loading of the DPF)?

Do you work together with partner companies?

What is the service like?

How long has the company been in business (experience)?

Perform DPF cleaning privately as not efficient

From our professional point of view, we can only advise you against independent diesel particulate filter cleaning using DPF cleaners for private use. Because: with these private cleaners you will probably rarely achieve even a halfway satisfactory result. The chemical-based cleaners or cleaning solutions are often even harmful to your DPF or engine. As a result, expensive damage can occur. So, if you need to clean your DPF, it’s worth going directly to professionals like us and avoid follow-up costs.